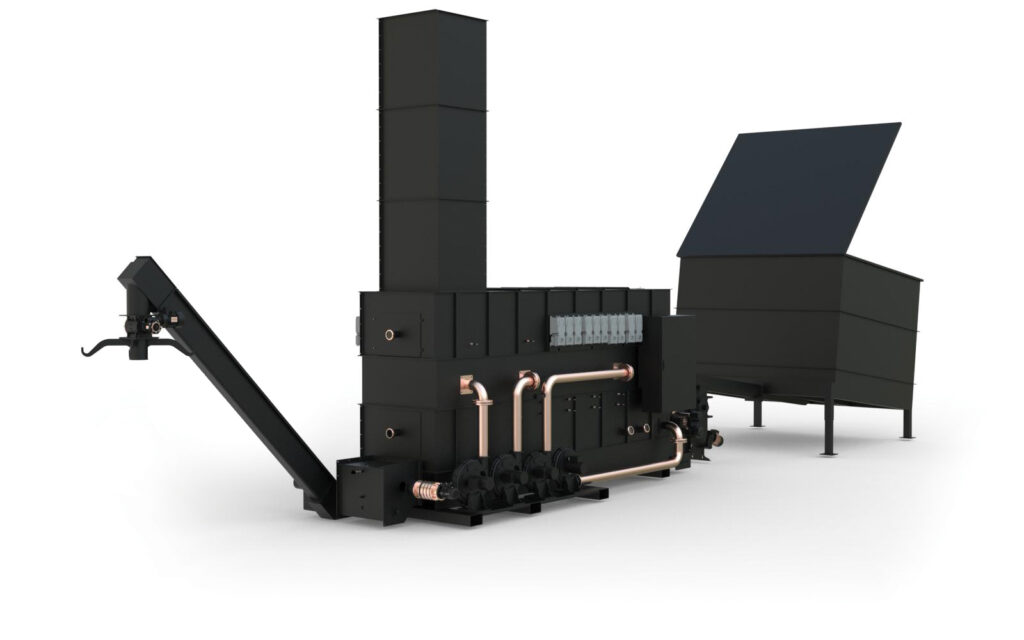

OG1-BCDR

> Biomass carbon removal technology

> CO2 Removal Operations

> Proprietary Pyrolysis for Scale 0.5 t* / h – 5.5 t / h (*metric)

Unique Scaled Technology

Unseen in the BCR space to date – industry-leading features of this continuous flow pyrolysis machine include:

- robust “universal workhorse” design, best available materials

- ease of operation

- practical components for globally adaptable scale

The inbuilt dryer can process feedstock with a moisture content up to 45%, allowing for significant cost savings, material handling reduction, and range of feedstock acceptance.

OG1-BCDR comes with staff training, servicing support, parts warranty, and ongoing updates.

Key Features

- Adheres to Puro.earth and Isometric CDR methodology

- Fully automated

- Real-time mass and energy balance!

- HTML-based HMI software for laptops and iPads

- Data collection, MRV system compatible

- Remote operable access, remote support

- Moisture sensing for feedstock and carbon

- Automatic water dosing quenching

- No dryer needed

- Best available materials, designed for high temperatures and chemically compatible against carburation and volatilisation

- High carbon content and low PAHs biochar

- Typical emission levels with sawdust feedstock (45% moisture content):

- Particulate matter <10 mg/Nm3

- Carbon monoxide (CO) < 50 ppm (in dry flue gas @ 6% residual O2)

- Nitrogen oxides, NOx <50 ppm (mixture of nitrogen monoxide and dioxide, 95% NO, 5% NO2)

*ppm = part per million, 1mg / kg

About OG Carbon

OG Carbon is a pyrolysis CO2 removal business and technology manufacturer.

We are ideally positioned within the global industry with our own scaled continuous pyrolysis technologies and a team of industry leading originators and technical experts.

Our team differentiated ourselves over decades, through thermodynamic excellence, market trading, output usage, and as CDR innovators.